METAL ALLOYS used in vintage & antique jewellery - a little science for you

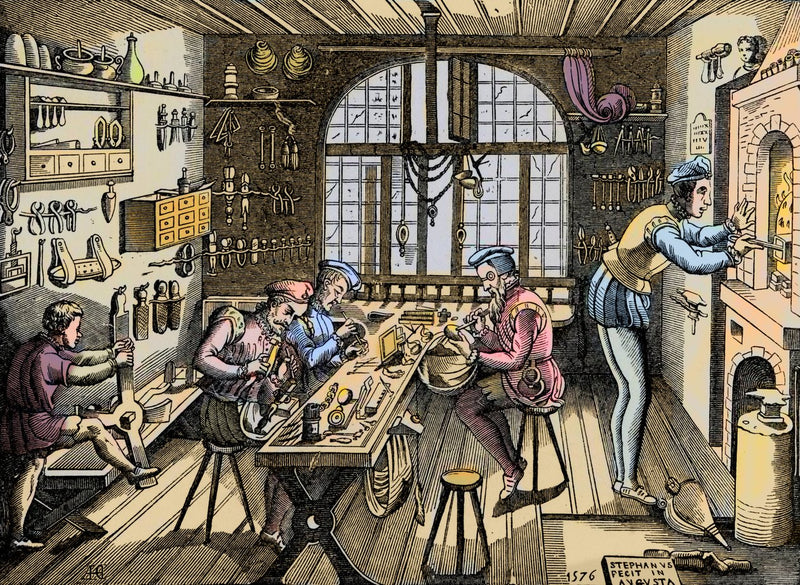

The price of Gold is at an all time high, making Gold jewellery expensive and jewels made from alternative metals more affordable. Throughout the centuries this has always been the case and goldsmiths have always sought and experimented with alternatives to use. We see many mysterious metals used in the vintage and antique jewellery which passes through our hands. Whilst we can test the various carats of Gold, Silver and Platinum (sometimes even these give us surprises), much of the base metal we can't test and so have to be circumspect in our descriptions.

Some of these base metals have become very desirable and much sought after. Genuine Pinchbeck (which was invented in the early 18th century by one Christopher Pinchbeck) is a most wonderful bright golden hue with a beautiful matt texture, and best of all it doesn't tarnish (see earrings on the left).

The information about many of these alloys is almost lost to time..... except that we happen to have a copy of SPON's Workshop Receipts (recipes to you and I) which gives the following information, taken directly from the text:

General Properties of Metal Alloys

Alloys are compounds of two or more metals, and each may be regarded as a new metal since it generally possesses properties different from those of the metals of which it is composed; but as the properties resulting from the combination of two metals rarely represent the mean of those metals, it is impossible to foretell the nature of a new alloy.

All true alloys consist of compounds of metals in their definite chemical proportions; it is, however, a matter of some difficulty to obtain them in a separate state, owing to the readiness with which they dissolve in the excess of that metal which may happen to preponderate. There are some few alloys also in which the constituent metals seem to be merely mechanically mixed.

Alloys possess the properties which are characteristic of metals, such as metallic lustre, conductivity of heat and electricity, and in a greater or less degree, malleability, ductility and tenacity.

Their fusibility does not at all depend on that of their constituents, but is generally greater; thus the melting point of tin is 235 degrees C, and that of lead 330 degrees C, whereas a compound of 5 parts of tin and one part of lead melts at 194 degrees C, and a compound of equal parts of both metals melts at 241 degrees C.

The ductility (ability for it to be stretched without breaking) of alloys is usually slightly less than that of their most ductile constituent, and their hardness is greater than the mean hardness of both or all the metals. The tenacity of an alloy is often much greater than that of either of the metals alone.

Precious metal alloys

Alloys of gold, silver and copper are generally superior in strength to any of the more fusible metals, and maybe forged either when red hot or cold. These three metals seem to unite in any proportions, and always form an alloy that is malleable when either hot or cold. Pure gold is but little used in the arts: it is too soft. It is generally alloyed with silver and copper, both to harden it and to depreciate its value. Alloyed with copper it forms gold of a red tint, with silver it forms gold of a green tint, and alloyed with both copper and silver, it gives intermediate tints.

Pure Silver is but little used alone. It is generally alloyed with a small amount of copper, which does not change its colour, and greatly improves its malleability and working qualities.

Jewellers Alloys

The following are summarised from Adolphe Fesquet (a writer on metallurgy):-

Algiers Metal: (a) 90 tin 10 antimony (b) 94.5 tin, 5 copper, 0.5 antimony. (a) is used for spoons and forks (b) for small handbells.

Argentin: 85.5 tin, 14.5 antimony ; suitable for spoons and forks.

Ashberry Metal: 78 to 82 tin, 16 to 20 antimony, 2 to 3 copper.

Blue Gold: 750 gold, 250 iron; prepared by dipping iron wire into molten gold, then casting, hammering and passing through a draw-plate.

Brittania Metal: (a) 9 tin, 1 antimony; (b) 80 to 90 tin, 5 to 10 antimony, 0.5 to 2 zinc, 1 to 3 copper; (c) 85 tin, 5 antimony, 5 bismuth, 1.5 zinc, 3.5 copper.

Chrysocale: 9 copper, 8 zinc, 2 lead.

Common Jewellery: 3 refined copper, 1 old Bristol bronze, and 25 tin for every 100 copper, the tin being replaced by a compound of lead and antimony where a fine polish is needed.

Dipping Metal: 48 copper, 15 zinc.

English Metal: 88 tin, 2 pure copper, 2 brass (containing 75 copper, 25 zinc), 2 nickel, 1 bismuth, 8 antimony, 2 tungsten.

Feuille morte: (dead leaf): 700 gold, 300 silver.

Fine Gold: 750 gold, 250 silver

Gilding Metal: 4 copper, 1 brass (containing 3 copper, 1 zinc) and 70 tin for each 80 copper.

Jewellery Gold: 38.85 gold, 5.70 silver, 10.20 copper.

Mannheim Gold: (a) 10 copper, 1.4 brass (containing 3 copper, 1 zinc), 0.1 tin (b) 3 copper, 1 zinc, 0.5 tin.

Minofor: 3.25 copper, 67.5 tin, 17 antimony, 8.95 zinc.

Mock Gold: (a) 16 copper, 7 platinum, 1 zinc (b) 100 copper, 17 tin, 6 magnesia, 3.6 sal ammoniac, 1.8 quicklime, 9 bitartrate of potash; the copper is melted first, and the magnesia, ammonia, lime and potash are successively added in small quantities; finally the tin is introduced in fragments, and the whole fused for 35 minutes.

Pinchbeck: Copper, 5lb; zinc, 1lb.

Plate Pewter: 90 tin, 7 antimony, 2 bismuth, 2 copper.

Queen’s Metal: (a) 3 to 9 tin, 1 antimony, 1 bismuth, 1 lead, (b) 2 copper, 50 tin, 4 antimony, 0.5 bismuth, (c) 24 brass (containing 7 copper, 3 zinc), 96 antimony, 30 tin, (d) 0.8 antimony, 18 bismuth, 32 lead.

Red Gold: 750 gold, 250 copper.

Ring Gold: 49.60 coin gold, 12.30 silver, 23.60 refined copper.

Tombac: Copper,16lb; tin 1lb; zinc1lb.

Tubania: (Engestrum): 4 copper, 8 antimony, I bismuth, added to 100 tin.

Tubania: (English): 12 brass (containing 7 copper, 3 zinc) 12 tin, 12 bismuth, 12 antimony.

Tubania: (German): 0.4 copper, 3.2 tin, 42 antimony

Tubania: (Spanish): 24 iron and steel scraps, 48 antimony, 9 nitre; the iron and steel are heated to whiteness, and the antimony and nitre gradually added; 2 ounces of this is alloyed with 1lb tin. A little arsenic is an improvement.

Vert D’eau (water green): 600 gold, 400 silver.

White Gold: gold whitened by addition of silver.

Yellow (antique) Gold: pure gold.

Yellow dipping: 2 bronze (containing 7 copper, 2 tin, 3 zinc), 1 copper and 10 tin for each 640 of copper.